MIL-C-18757/5A(OS)

4.6.6 Protective coating tests. Cartridge cases shall be prepared and tested in accordance with the

protective coating test of MIL-C-18757. The presence of white corrosion products will be permissible to

the extent that it does not interfere with chambering of the cartridge case. The black speck corrosion

rating procedure shall be as specified in OD 47471.

4.6.7 Chamber gage examination. Each cartridge case shall be chamber-gaged in receiver, Drawing

3030497, to determine conformance to the requirements of 3.7. A gage removal force of 35 pounds

maximum is permitted.

4.6.8 Ballistic test. The cartridge cases shall be loaded in accordance with Drawing 5366338. The

propellant charge shall be adjusted so that the ballistic test pressure at any temperature is as follows:

Service rounds 17.0 to 19.0 tsi-copper

Proof rounds 20.8 to 21.8 tsi-copper

Testing shall be performed in a Mk 75 gun mount and in quantities specified in table II.

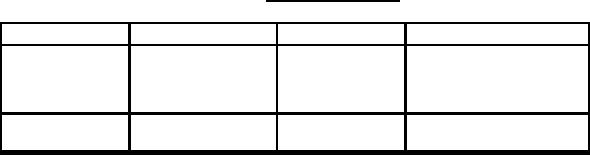

TABLE II. Ballistic acceptance.

Type of lot

Number of round

Type of round

Round temperature EC

First article

70

Service

32

30

Proof

32

25

Service

49

25

Service

-7

401

Service

32

Production

101

Proof

32

1

After firing, cases shall be rechambered in chamber gage.

4.6.8.1 Test procedure. All proof pressure rounds and five service rounds at each temperature, all

containing copper crusher gages, shall be fired in the single shot mode to determine compliance with the

pressure requirements. The remainder of the cartridges shall be fired in the automatic mode.

Temperature of the rounds shall be as specified in table II. Rounds shall be temperature conditioned for a

minimum of 24 hours.

4.7 Inspection of packaging. Packing and marking shall be visually examined for conformance to

section 5.

5. PACKAGING

5.1 Packing. Packing shall be in accordance with MIL-C-18757 with four cases packed in each box.

Each case is to be packaged in a bag in accordance with MIL-P-117, Type III, Class E, Style 1.

Approximate size of bag is 8.5 x 33 inches. Place a one unit bag of desiccant, per MIL-D-3464, Type I,

inside before sealing. Close bag and seal with tape conforming to PPP-T-70. PPP-T-60 may be used as

an alternate tape.

7